The History of Lead Mining

The Derbyshire Peak District has long been an important area for lead mining. In geological times mineral rich magma was introduced into fissures and faults in the existing limestone. It cooled and crystallised, leaving deposits of Lead Ore surrounded by crystals of Fluorspar and Calcite. The term Rake is used to describe a major vein of this material. Derbyshire lead ore, known as Galena was first smelted approximately 3,500 years ago.

Lead mining and smelting was an established industry in 1086, when the mines at Bakewell were recorded in the Domesday Book. The Romans made it an important industry and for two hundred years- up to 1780, the Peak District was the most important lead mining area in the world.

During the 1600s lead was second in importance to the national economy only to wool. It was essential for roofing new houses for nobility and for public buildings. All houses by then had glazed windows, with lead glazing bars. It was also the only material in use for water storage and piping. Every Army used lead ammunition. Lead was also a thriving export trade.

Youlgrave was once an important lead mining parish. Five lead mines were mentioned in the 1857 Directory of Derbyshire, with details given of mining activity in Youlgrave as follows: “(In 1851) the inhabitants are principally employed in the mines, but these are not so profitable as they were some years ago. The principal mines now worked are the Longrake, Townend, Youlgreave Ashes, Canton Hill Pipe, and Ladycroft, the former of which is the most productive.”

The History of Long Rake Spar during the 1800’s

The mine at Long Rake was officially opened in 1867. The land at this time was owned by the Staley and Shimwell families from the local village of Youlgrave. W.G. Cooke and Co. undertook the operation of the mine to extract Calcite, Fluorspar and Lead Ore. By 1872 production from the mine was in full swing.

Local land owner Thomas Shimwell bought the mine nearly ten years later, and renamed the company the Long Rake Spar Mining Company in 1881. Extraction continued to expand, and W.G. Cooke & Co. were chiefly concerned with the extraction of bright white Calcite, more commonly known as Derbyshire ‘Spar’. The sparkling aggregate was used across Victorian Britain, mainly for gardens and driveways as well as pebble dashing, in Terrazzo flooring and tarmac roads.

In 1899 shares were first issued at a value of 1 share to a pound. The operations at the site were now taking place underground at 3 levels, as well as above ground at the surface works to process the extracted materials. The mine consisted of three distinct levels below ground at 300, 375 and 420 feet, with most activity taking place on the 300-foot level, which was railed throughout and was less prone to flooding.

The 1900’s

In 1913 the landowner (now Joseph Shimwell) gifted the mine and its surrounding land to his daughter Miss Mary Shimwell as a source of income. Mary Shimwell employed James Moores as Director of the Company. At this stage the Long Rake mine employed 6 men working on the surface and between 2 and 6 men working below ground. The Long Rake Spar Mining Company now became Long Rake Spar Co. as we know it today.

In the 1920’s the company was directed by Captain Percy Potter who lived in Youlgrave Village. His directorship saw an ever expanding increase in the output of the mine. At this time Long Rake Spar Co. Ltd employed twelve miners and produced 12,200 tons of Calcite (Derbyshire Spar) and 100 tons of Lead Ore every year. This product was distributed across the UK. Captain Potter’s wife also joined the board of directors.

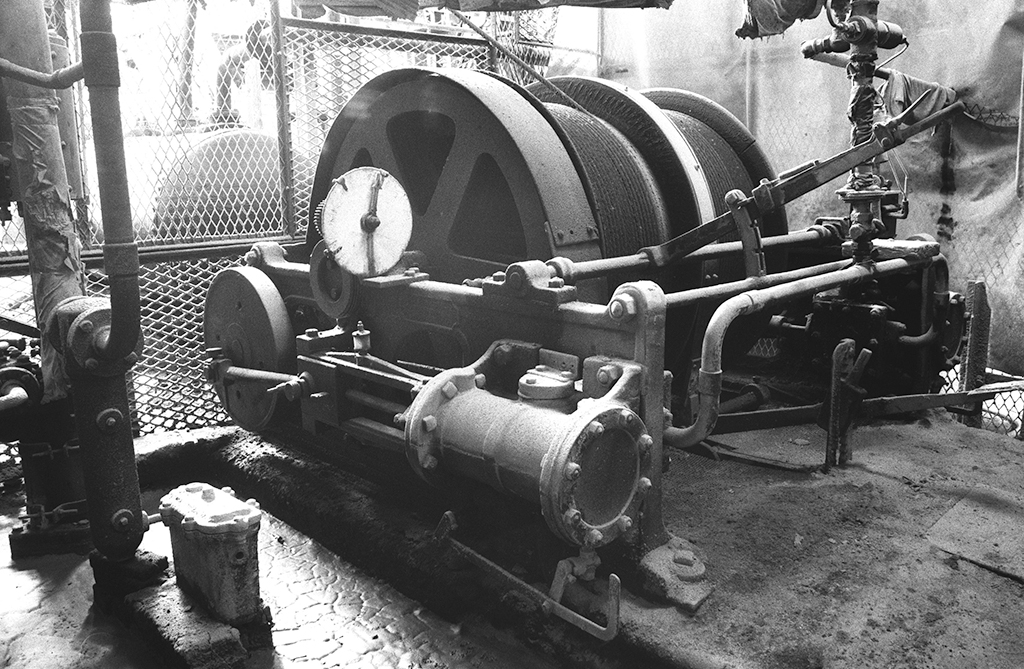

1936 saw the arrival of electric locomotion in the mine. Greenwood and Batley supplied the first haulage wagons and rails to Long Rake Spar on 22nd July 1936. Electric haulage was used on the 300 and 375 foot levels and improved the transport speeds of mined materials from the tunnels to the works above. The surface works at this time separated the Spar from any excess lead and washed the products ready for use. The dry plant then separated the pure white Spar into five different grading sizes and prepared them for distribution.

Following Miss Mary Shimwell’s death in 1954. Captain Percy Potter and his wife bought the lease from her estate. They continued to direct the company alongside Mr. N Lever and the mine continued to expand.

By 1964, Long Rake Spar was employing 15 miners below ground and with more employees in the surface works. The mine now extended to just over 2 kilometres. The vein at the 300 level had been nearly completely excavated. Mr J. F. Spedding, who worked for the company as the Works Manager under the Potter’s directorship, remarked that the stopes between the tunnels were “big enough to put a Catherdral in”.

In the 1970’s the Long Rake Spar Co. was sold by Captain Percy Potter to Derbyshire Silica Firebrick (DSF) and continued to operate as Long Rake Spar Co. Ltd. Only 2 men were mining the Spar and the surface plant had started to process material brought from other mines and quarries. During the late 1970s the previously flooded 500 level was drained and started being explored.

Owing to the falling price of calcite and increasing poor returns for ore, the mine finally finished excavation in 1981. The company did however continue to operate above ground in the surface plant.

In 1985 Long Rake Spar Co Ltd was taken over by T and T Broadhurst. Trevor Broadhurst, his father Tom and his mother Jean bought the company and immediately began to expand the facilities at the plant and the variety of aggregates that Long Rake Spar supplied.

T and T Broadhurst had previously been involved in Calcite, Fluorite and Barite exploration in other local areas and intended to develop the processing facilities at Long Rake Spar. The company began to diversify, expanding into mineral processing by installing washing, blending and drying equipment to target more specialist market sectors. This growing expertise allowed Long Rake to become the original suppliers of an expanding range of dried aggregates.

Technological advances in mineral processing meant that the washing, blending and drying capabilities at the Derbyshire site were able to meet the changing trends and high demands of the construction industry; allowing Long Rake to contribute to some of the UK’s largest building projects in the 1980s and early 1990s.

Throughout the 1990s large investments were made in the technical development of the company as the drying infrastructure and bagging equipment was improved. Long Rake Spar began processing materials from further afield and distributing them to a larger number of customers with a widening variety of requirements. Decorative products for landscaping and retail sale were developed and in 1998 the Grantex range of products was launched on the dry side.

The 2000’s

In 2009 Long Rake Spar continued to expand and this time further afield with the acquisition of Meadow View Stone in Prees, Whitchurch. Meadow View Stone was purchased to exclusively supply directly to the Garden Centre trade. This opened up a new channel for high quality decorative aggregates and led to the development of Meadow View’s award-winning Point of Sale and market leading merchandising and display gardens. Meadow View Stone has become an established and trusted supplier to the Garden Centre trade.

In 2015 Long Rake Spar welcomed further expansion with a new strategic dock site in Rye Harbour, East Sussex. This 20 acre site provides valuable storage and manufacturing capacity and enables overseas shipments at the dockside location.

2020 saw Long Rake Spar invest in a site at Garston Docks. This 10 acre site provides dockside storage as well as production facilities, providing the ability to increase stockholding and production capability.

Long Rake Spar Co. Ltd continues to be one of the largest importers and suppliers of aggregates to the construction and landscaping industry in the UK.